ULTRA.ROLL - Roller screws

Vorteile von Rollengewindetrieben

- Significantly higher power density compared to conventional drive spindles such as ball screws or trapezoidal spindles

- Unrivaled combination of dynamism and power

- Accuracies of up to 6µm / 300mm (G1) path variations possible

- High repeatability and positioning accuracy

- Compact drive solution

- Ideal solution for servo presses, dosing, riveting processes, safety valves, hygiene and pharmaceutical applications

Your benefits with ULTRA.ROLL - roller screws

- Standard and long-term development projects

- Customized adaptation of spindle, nut and bearing unit from a single source

- Highly integrated nut and spindle design possible

- Development laboratory and experts

All designs available:

- Roller screws with roller return

- Roller screws without roller return

- Inverted roller screws

- Planetary screw drives

How does a roller screw drive work?

Performance range of ULTRA.ROLL roller screws

| Performance features | Min | Max |

|---|---|---|

| Cstat | - | 4000 |

| Cdyn | - | 1300 |

| Diameter | 15 | 120 |

| Gradient | 1 | 40 |

| Length | - | 3000 |

| Accuracy | G1 | G5 |

| Further features | Your advantages |

|---|---|

| Nut designs |

Fully customizable according to customer drawing: - End and center flange nut - cylinder nut - Double nut - Special nut with additional mounts and highly functionally integrated ...and much more! |

| Special mother | Integration of screw-on surfaces, anti-rotation locks, centering, cardan bolts, etc. |

| Spindle bearing | High-performance range for round flange or standing flange solutions, optimized for heavy-duty applications in various bearing positions Fully sealed and lubricated for life |

| Field of application | All applications that require the highest load ratings, service life, low-noise operation and integration |

| Service life | Will be charged |

| Delivery time | 14 weeks from order placement, express production on request |

Do you have requirements that you could not find?

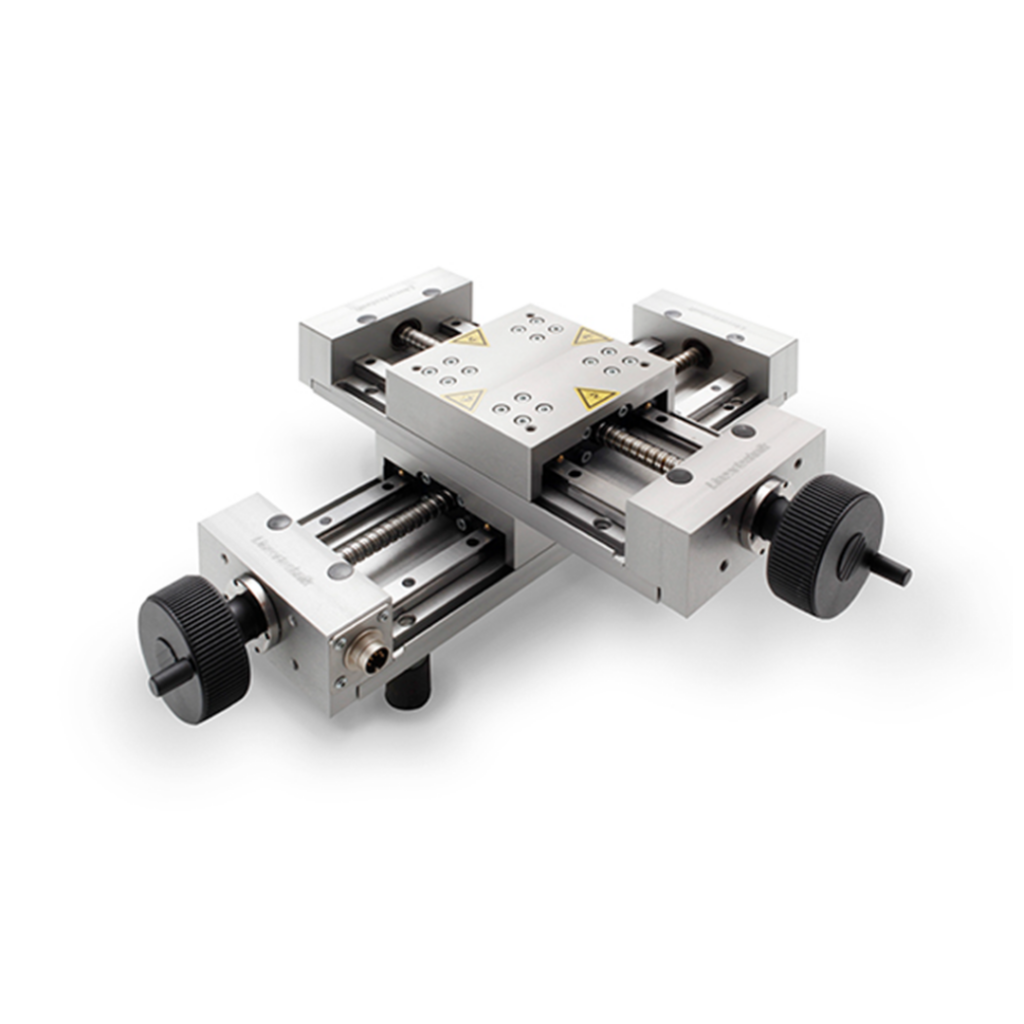

Special solutions, bearing units and references from ULTRA.ROLL - Roller screws

- Large number of completed development and series projects

- Years of experience, know-how and expertise in the field of roller screws and precision spindles of all designs

- Highly integrated design possible

- Design, development and production of roller screw drives & associated heavy-duty bearing units

- Fast delivery time and constructive design

Your path to a customized solution

01

Determination of requirements

Let us know what you need - our experts will analyze your requirements to find the right solution for you.

02

Individual advice

Benefit from a personal consultation in which we work together to select the optimum components for your application.

03

Solution development

Our team will develop a customized solution that is precisely tailored to your specific needs.

04

Implementation and support

Once a solution has been found, we support you during implementation and assist you with our after-sales support.

What are the differences between the designs of roller screws?

There are basically three different types of roller screw drive:

- Roller screws with roller return

- Roller screws without roller return

- Inverted roller screw drive

The roller screw drive with or without roller return differs mainly in the type of roller guide. The simpler design is the roller screw drive with roller return. At the end of a pitch, the planetary roller is moved to the next "gear". This simplified design has a positive effect on the price, but is limited in terms of precision and speed.

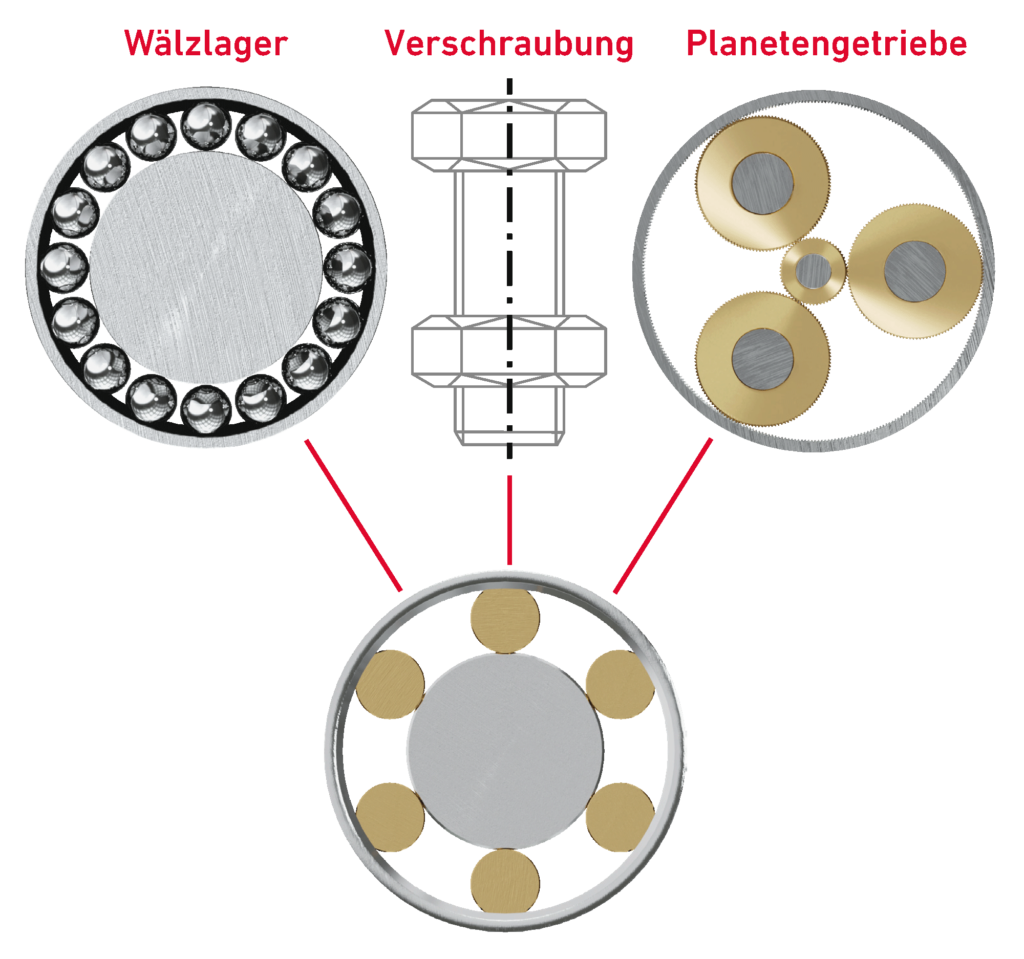

In roller screws without roller feedback, the spindle is synchronized to the nut via planetary gearing. This eliminates the need to reposition the planetary roller, which enables higher speeds, accelerations and positioning accuracies.

Inverted roller screws differ fundamentally in their design from all other mechanical drive screws. This design consists of a nut tube, planetary rollers and a push rod. All components are inverted, i.e. the thread is located in the nut tube and the push rod moves instead of the nut. This is ideal for applications in the hygiene sector, where installation space is limited and as a replacement for hydraulic lifting cylinders.

How does the ball screw differ from the roller screw?

The drive types differ in terms of load capacity, speed, precision, efficiency and price. The different performance characteristics are shown qualitatively in the illustration below.

In order to make a measurable statement in facts and figures, the respective application must be considered in detail. Ground ball screws, for example, are very precise drives, but this also has a direct impact on the price.

With regard to modern production possibilities, it is therefore always worth considering the use of a roller screw drive as soon as one of the following cases applies:

- Less installation space available

- High power density required

- Large acting forces & dynamics

- High ambient temperatures

- High safety requirements (failsafe application)

What is a planetary screw drive or planetary roller screw drive?

Planetary screw drives or planetary roller screw drives are alternative names for roller screw drives.

Planetary screw drives represent a different, alternative design.